Introduction

The old tractor in the back of my grandfather’s barn had been silent for months. One hot afternoon in July, the axle bearing seized so badly that the wheel wouldn’t budge, no matter how much we pried or pranged the metal. That’s when we brought out the proper tool: a bearing puller. In less than an hour, with the right puller, we removed the bearing, replaced it, and the tractor roared back to life. That moment taught me how a simple yet properly chosen tool can save hours of labor, thousands in repair costs, and preserve the integrity of the machinery.

In an industry where the global bearings market was worth USD 120.98 billion in 2023 and is projected to reach about USD 226.6 billion by 2030, growing at a compound annual growth rate (CAGR) of ~9.5%, the role of all tools in bearing maintenance including pullers is critical.

Moreover, unplanned downtime due to bearing failure can cost manufacturers $5,000 to $50,000 per hour, depending on production scale.

What Is a Bearing Puller?

A bearing puller is a tool designed to safely remove bearings (or similar components like gears, pulleys, couplings) from shafts or housings. It does so by applying controlled force in a way that avoids damage to the bearing’s races, the shaft, or surrounding parts.

Most bearing pullers have some combination of:

- Jaws or claws (arms) to grip the bearing (outer race, inner race, or bore),

- A forcing screw or hydraulic ram to push against the shaft or backing surface,

- Supporting components like crossbars, hex heads, separators, or expanding sleeves.

How Bearing Pullers Work

- Attachment & Setup: You choose the appropriate puller type, grip the bearing (outer or inner), align everything properly.

- Force Application: Either manually via screw-turning or via hydraulics.

- Extraction: The bearing gradually slides off the shaft or out of its housing without damaging the mating parts.

Using the wrong tool or method can cause damage, extend downtime, or even lead to more costly failures.

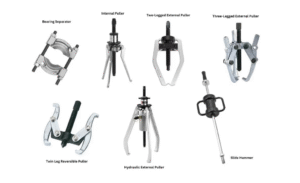

Types of Bearing Pullers & Their Uses

| Puller Type | How It Grips / Works | Best Use Cases / Advantages |

| External Puller (two-jaw & three-jaw) | Grips the outside (outer race) of the bearing | When you can access the outer race; two-jaw for tight spots, three-jaw for better stability and when more pulling force is needed |

| Internal Puller (Blind Puller) | Grips inside the bearing’s bore or inner race using expanding sleeves, collets, etc. | For bearings seated deep in housings or recesses where the outer race is not accessible |

| Bearing Separator | A flat, split plate that slides behind the bearing to create space for the puller jaws | When there’s limited clearance behind the bearing and standard external pullers won’t fit |

| Reversible Puller | Arms that can invert or reverse its grip to work internally and externally | Good when one tool is needed to handle both internal and external removal, saving cost and space |

| Hydraulic Puller | Uses hydraulic cylinders/pumps for high, controlled force | For large, tightly fitted bearings especially in heavy machinery where manual force is impractical |

| Slide Hammer Puller | A shaft with a sliding weight; when the weight strikes, it delivers axial impact force | Useful with internal pullers, especially for blind holes or when the bearing is stuck and needs impact to begin loosening |

Applications of Bearing Pullers

Bearing pullers are used in many fields:

- Automotive: wheels, engine components, gearboxes, axles.

- Industrial Machinery: motors, pumps, conveyors, gearboxes in factories.

- Heavy Equipment: construction, agriculture, mining machinery (excavators, tractors, etc.).

- Electrical Devices & EVs: as electrification increases, precise bearings and their removal become more critical.

Given that Asia-Pacific accounted for ~41% of the global bearing market in 2024 and is among the fastest growing regions, demand in manufacturing and automotive there drives intense use of bearing pullers.

Buying Guide: What to Consider

When selecting a bearing puller, keep in mind:

- Bearing Size, Reach & Spread: Measure inner/outer diameters, make sure the puller can reach behind the bearing or fit in tight spaces.

- Number of Legs (2 vs 3): Two-leg pullers are easier to fit in constrained spaces; three-leg gives better balance and force distribution.

- Force Capacity / Load Requirements: Hydraulic or heavy mechanical pullers for large or stubborn bearings; lighter manual ones for smaller or less frequent use.

- Material & Durability: High-strength steel, hardened jaws, good finishing to avoid wear or damage under load.

- Accessibility & Clearance: Internal pullers, separators, slide hammers for difficult to access bearings.

- Frequency of Use: If you’ll use pullers often (e.g. in a workshop), quality investment makes sense; for occasional use, simpler pullers may work.

- Safety Features: Solid build, secure jaws, reliable screws/hydraulics, ability to align to prevent damage.

Maintenance of Bearing Pullers

To get long life and reliable performance:

- Clean after use remove dirt, grease, any corrosion.

- Lubricate threaded screws, hydraulic components.

- Inspect jaws for bending or cracking; check threads for wear.

- Store in dry conditions; protect from rust.

Why Using Proper Pullers Matters: Costs & Risks

- A single bearing failure that halts production for 4 hours can cost between USD $20,000 to $200,000 in some heavy-industry settings.

- Unplanned downtime can represent up to 11% of annual revenue for large manufacturing plants.

- Using incorrect removal methods risks damage to shafts or housing, increasing repair costs significantly.

Conclusion

Bearing pullers might seem like niche tools in the toolbox, but their correct use has outsized impact: reducing downtime, preventing collateral damage, saving on repair bills, and keeping machines running safely. With the global bearing market expected to grow from over USD 120 billion in 2023 to more than USD 226 billion by 2030, and with unplanned downtime costing tens of thousands of dollars per hour in heavy-industry applications, selecting the right puller type, size, and quality matters more than ever.

Are you ready to choose the right bearing puller for your situation?

You may also like to read: How to Fix a Leaky Faucet: A Comprehensive Guide